Explore the innovative use of 3D printed atomizer baskets for efficient evaporation processes.

Evolution of Atomizer Technology

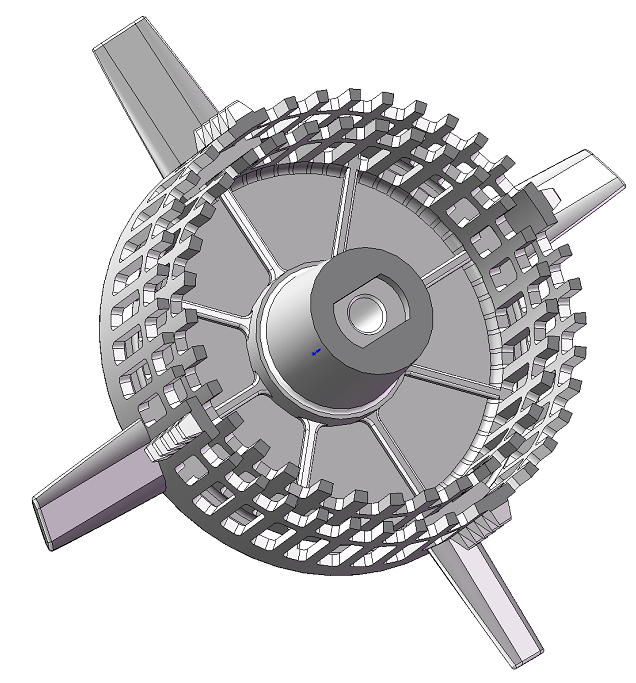

Atomizer technology has evolved significantly over the years, with advancements in materials and manufacturing techniques. The introduction of 3D printing has revolutionized the way Evaporation King's atomizer baskets are designed and produced. This cutting-edge technology allows for the creation of intricate and customized atomizer baskets that were previously not possible.

Traditional atomizer baskets were typically made from metal or plastic, and their design was limited by the constraints of traditional manufacturing methods. With 3D printing, intricate geometries and complex structures can be easily created, leading to enhanced atomization and evaporation efficiency.

Examples of Traditional Built Atomizer Baskets

Examples of Traditional Built Atomizer Baskets

The evolution of atomizer technology has paved the way for the development of Evaporation King's 3D printed atomizer baskets, offering improved performance and versatility in various applications.

Benefits of 3D Printed Atomizer Baskets

The use of Evaporation King's 3D printed atomizer baskets brings several benefits to the evaporation process. Firstly, the ability to customize the design allows for optimal atomization and evaporation efficiency. The intricate geometries and tailored features of the basket can be specifically designed to meet the requirements of the application, resulting in improved performance.

Evaporation King's 3D printing enables the production of atomizer baskets with complex internal structures, such as microchannels or cavities, which can enhance the evaporation process. These internal structures provide increased surface area for evaporation, leading to faster and more efficient evaporation rates.

Evaporation King's 3D printing offers cost-effective manufacturing solutions for atomizer baskets. The ability to produce baskets on-demand and in various materials reduces production costs and lead times. This makes our 3D printed atomizer baskets a viable option for both small-scale and large-scale evaporation processes.

Overall, the benefits of Evaporation King's 3D printed atomizer baskets include improved performance, enhanced customization, and cost-effectiveness. Evaporation King continues to lead the industry by introducing a range of innovative 3D atomizer designs that utilize unique shapes and materials to greatly enhance performance.

Design and Customization Options

The design and customization options available with 3D printed atomizer baskets are virtually limitless. 3D printing allows for the creation of complex geometries and intricate internal structures that can optimize atomization and evaporation efficiency.

The Evaporation King design process starts with a digital model of the atomizer basket, which can be customized to meet specific requirements. Parameters such as the shape, size, and internal features can be adjusted to achieve the desired performance.

Custom EK Patent Pending Atomizer Basket for Extremely High TSS

In addition to design customization, 3D printing also offers a wide range of material options for atomizer baskets. Depending on the application and the properties required, materials such as metals, plastics, and ceramics can be used. This flexibility in material selection further enhances the customization possibilities.

Gladiator-120 Installation In High TSS Application

With 3D printing, Evaporation King's atomizer baskets can be tailored to suit the unique needs of each evaporation process, resulting in improved efficiency and performance.

Enhanced Evaporation Efficiency

One of the key advantages of Evaporation King's 3D printed atomizer baskets is their ability to enhance evaporation efficiency. The intricate internal structures and customized design of these baskets provide increased surface area for evaporation, resulting in faster and more efficient evaporation rates.

The complex geometries and tailored features of 3D printed atomizer baskets allow for optimal atomization, ensuring that the liquid is dispersed into micron-sized droplets. These tiny droplets have a larger surface area compared to larger droplets, enabling faster evaporation.

In addition, our customization options offered by 3D printing allow for the creation of atomizer baskets that are specifically designed for the properties of the liquid being evaporated. This further enhances efficiency by ensuring proper atomization and evaporation of the liquid. For example, low or high pH wastewater applications would require unique metals to withstand these corrosive environments. Titanium 3D printing looks promising for low and high pH applications. Check out the video below on current titanium 3D printing processes. Our current designs are easily printed using this type of titanium 3D technology.

Overall, the use of 3D printed atomizer baskets can significantly improve evaporation efficiency, leading to reduced processing times and increased productivity.

.jpg?width=413&height=430&name=IMG_1463%20(1).jpg) Intricate Titanium 3D Printed Product

Intricate Titanium 3D Printed Product

Future Prospects and Developments

The future prospects of 3D printed atomizer baskets in Evaporation King's evaporation processes look promising. As 3D printing technology continues to advance, you can expect further improvements in the design and performance of our atomizer baskets.

One area of development is the use of advanced materials for 3D printing atomizer baskets. Evaporation King is exploring the use of materials with specific properties, such as high thermal conductivity or chemical resistance, to further enhance the performance of the atomizer baskets.

Another area of focus is the optimization of the internal structures of the atomizer baskets. By studying fluid dynamics and heat transfer, Evaporation King aims to design internal structures that maximize evaporation efficiency with our industry leading 18,000 RPM motors.

Advancements in 3D printing techniques, such as multi-material printing or the use of composite materials, can open up new possibilities for atomizer basket design and performance.

Overall, the future of 3D printed atomizer baskets in evaporation processes holds great potential for further improvements and innovations.

With our innovative 3D printed atomizer baskets powering enhanced evaporation systems across the USA in demanding wastewater applications, reach out to us by clicking on 'Contact Us' below for further details on how our specialized atomizer baskets can cater to your specific requirements.